Description:

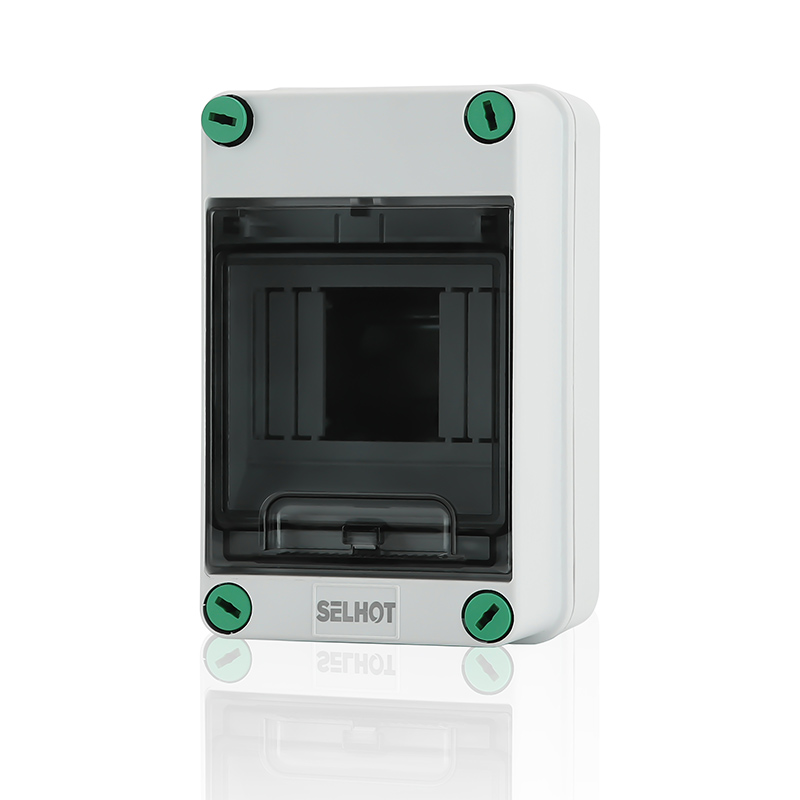

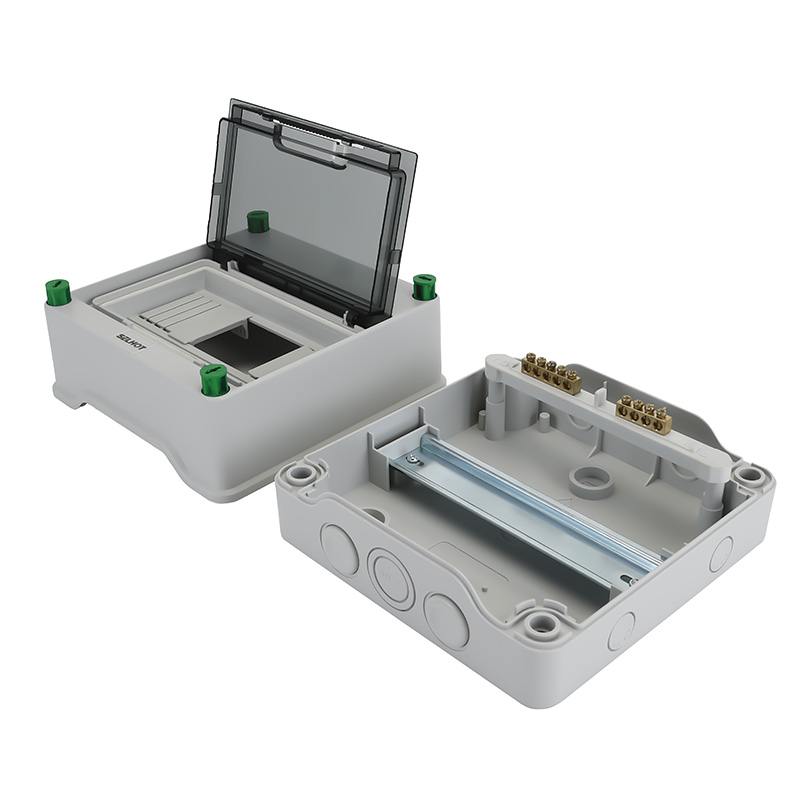

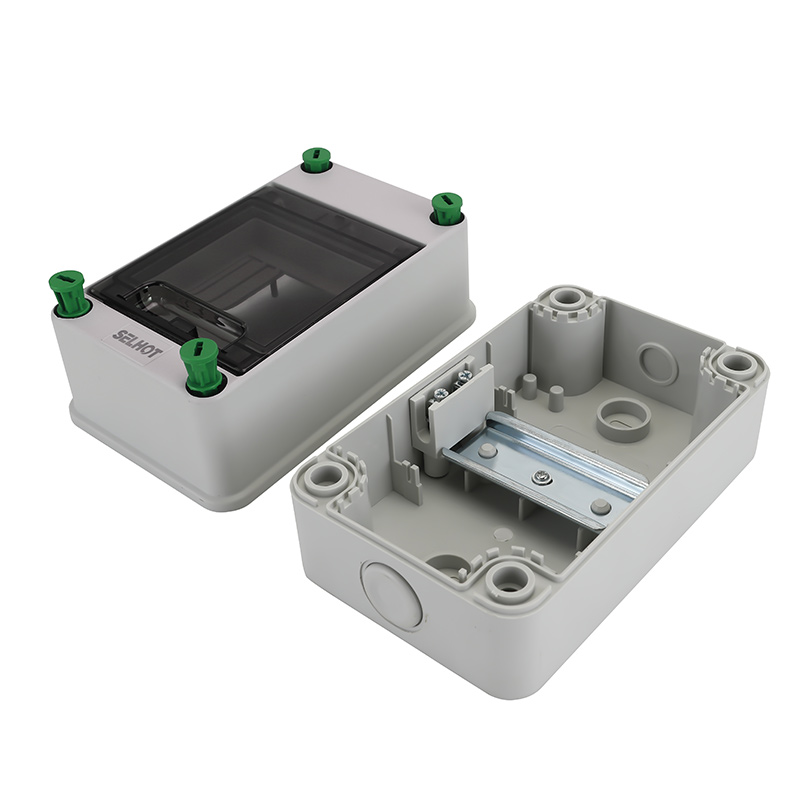

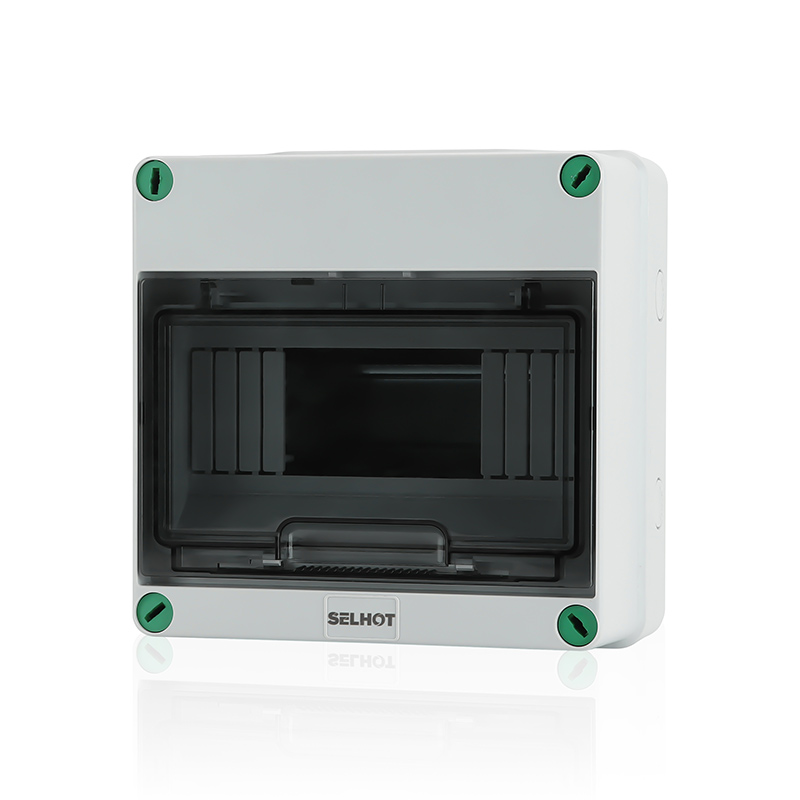

Removable Knockout Hole Waterproof Distribution BoxThese knockout holes are designed to be easily manoeuvred from inside the box, allowing the customer to simply push them aside when required for convenient wiring. This feature eliminates the need for tools or complicated manoeuvres during installation, greatly simplifying the process and saving time. When knockout holes are not required, they can be seamlessly pressed back into place, ensuring a seamless and aesthetically pleasing appearance. Significantly, even when the knock-out holes are retracted, the box retains its IP65 waterproof rating, ensuring protection from dust ingress and water jets from any direction, making it suitable for use in harsh environments.

Description:

Outdoor ABS distribution boxes are used in industries, homes, sunshade systems, communications, and circuit breakers. Before installing a small distribution box, you must first choose a suitable location. It is necessary to consider factors such as the use function, ventilation and heat dissipation of the electrical box, and choose a location close to the main power supply and easy to operate.

Characteristic:

Colour: RAL 7035

Type of cover: Cover

Transparent cover: Yes

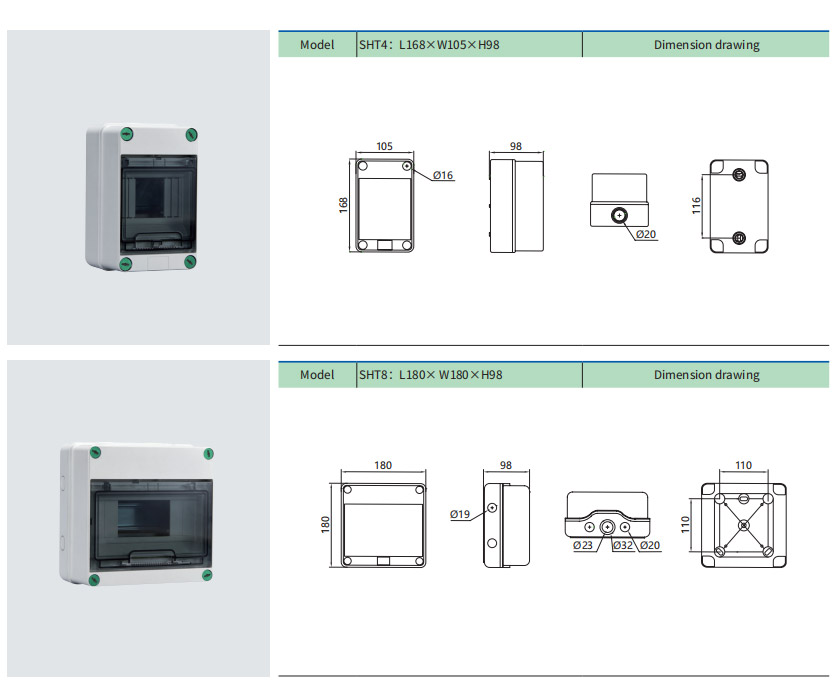

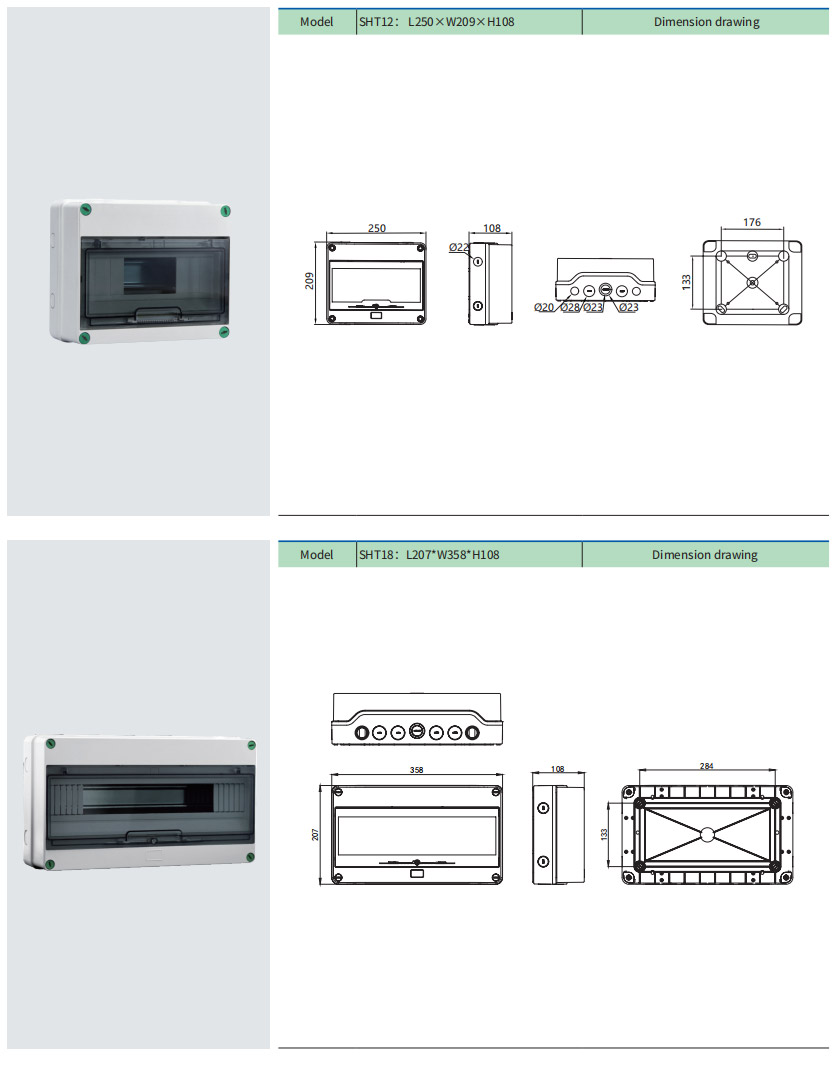

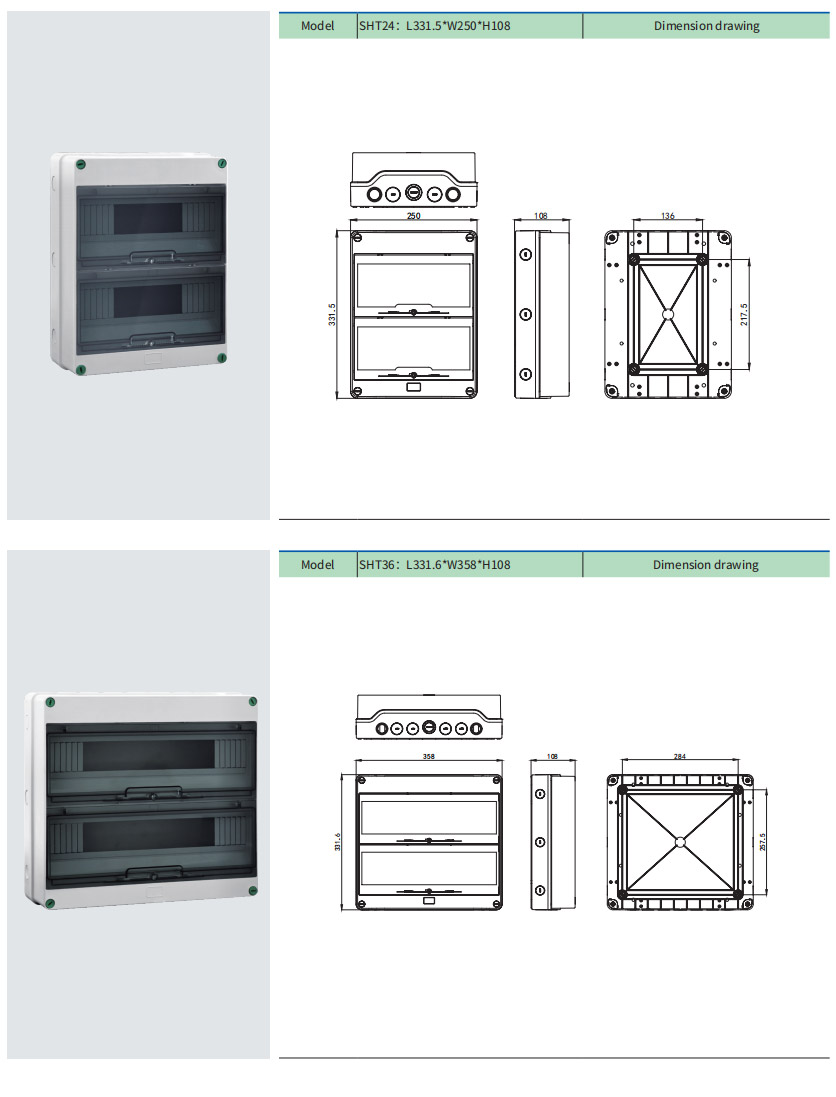

Number of modules: 4 way - 12 way

Number of rows: 1

Product accessories: DIN rail(s),Grand joint,Copper terminal

IP protection level: IP66

Impact protection class:IK08

ENVIRONMENTAL CONDITION

Application area: Indoor/Outdoor installation

Maximum ambient temperature 24 h: 35 °C

Ambient temperature: -5 °C up to +40 °C

Relative humidity: ≤ 50 % at 40 °C, ≤ 100 % at 25 °C

ELECTRIC BOX PERFORMANCE

Rated voltage: Un = 400 V

Rated insulation voltage:Ui:690V

Protection class:II

Rated current (of the terminal):In = 75 A

N separable:No

conforming to the standards:EN 60670-1, DIN EN 60670-24

MATERIAL CHARACTERISTICS

Material:ABS Shell / PC Door

According to IEC 60695-2-11 glow wire test temperature:650 °C

Temperature resistance:-25 °C up to +80 °C

Halogen-free:Yes

Silicone-free:Yes